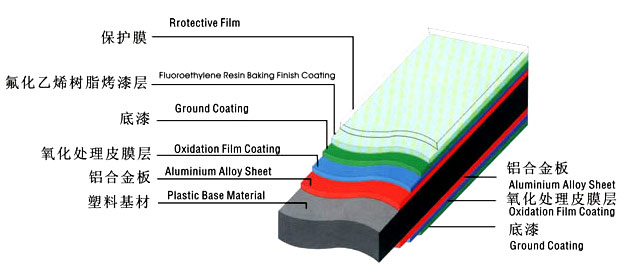

Aluminum plastic plate Aluminum plastic composite plate, referred to as aluminum plastic plate, is a new material made of aluminum plate with surface treatment and paint coating as the surface, polyethylene and polypropylene plastic as the core layer, and processed by a series of processes.

The aluminum plastic plate was first developed and produced by ALUDINGEN in Germany, and then improved by FORKEN and ALOCA. Since the 1990s, the production quality has gradually stabilized and reached a higher level. As the aluminum plastic plate is composed of two materials (metal and non-metal) with different properties, It not only retains the main characteristics of the original materials (metal aluminum, non-metallic polyethylene plastic), but also overcomes the shortcomings of the original materials, thus obtaining many excellent material properties, such as luxury, colorful decoration, weather resistance, corrosion resistance, impact resistance, fire prevention, moisture prevention, sound insulation, heat insulation, and seismic resistance; Light weight, easy processing and forming, easy handling and installation and other characteristics open up a broad application prospect for aluminum plastic plates.

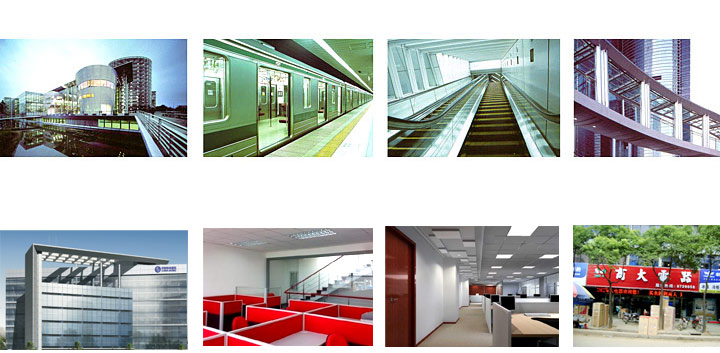

Due to many advantages in material performance, aluminum plastic plate is widely used in various architectural decorations, such as ceilings, wrapped columns, counters, furniture, telephone booths, elevators, storefronts, billboards, factory walls, etc. It has become the representative of metal curtain walls in the three major curtain walls (natural stone, glass curtain walls, metal curtain walls). In developed countries, aluminum plastic plate is also used in the manufacture of buses and train cars, sound insulation materials for aircraft and ships Design the instrument box, etc.

Aluminum plastic composite plate, referred to as aluminum plastic plate, is a new material made of aluminum plate with surface treatment and paint coating as the surface and polyhexene plastic plate as the core layer through a series of processing processes. The aluminum plastic plate was first developed and produced by ALUSINGEN in Germany, and then improved by FORKEN and ALOCA. Since the 1990s, the product quality has gradually stabilized and reached a high level. As the aluminum plastic plate is composed of two different materials (metal and non-metal), It not only retains the main characteristics of the raw materials (metal aluminum, non-metallic polyhexene plastic), but also overcomes the shortcomings of the raw materials, thus obtaining many excellent material properties. Such as luxury, beauty, colorful decoration; Weather resistance, corrosion resistance, impact resistance, fire protection, moisture-proof, sound insulation, heat insulation and seismic resistance; It is light in weight, easy to process and shape, easy to transport and install, and can be quickly completed. These properties open up a broad application prospect for aluminum plastic plates.

■ Product specifications:

1. Standard size: thickness (T): 1mm 2mm 3mm 4mm

2. Width (W): 1220mm 1250mm 1600mm

3. Length (L): 2440mm 3050mm

4. Special sizes can be customized according to customer requirements.

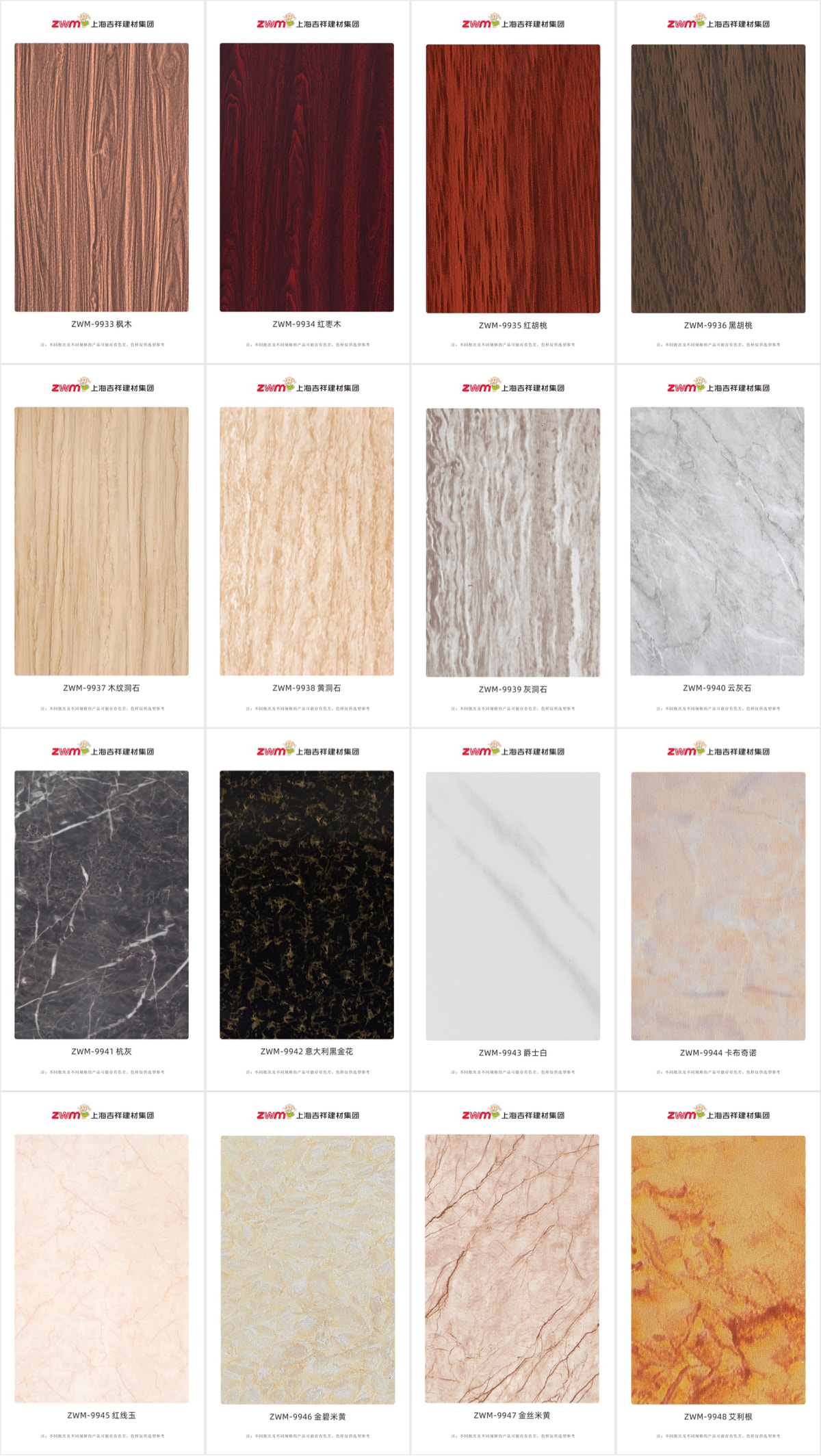

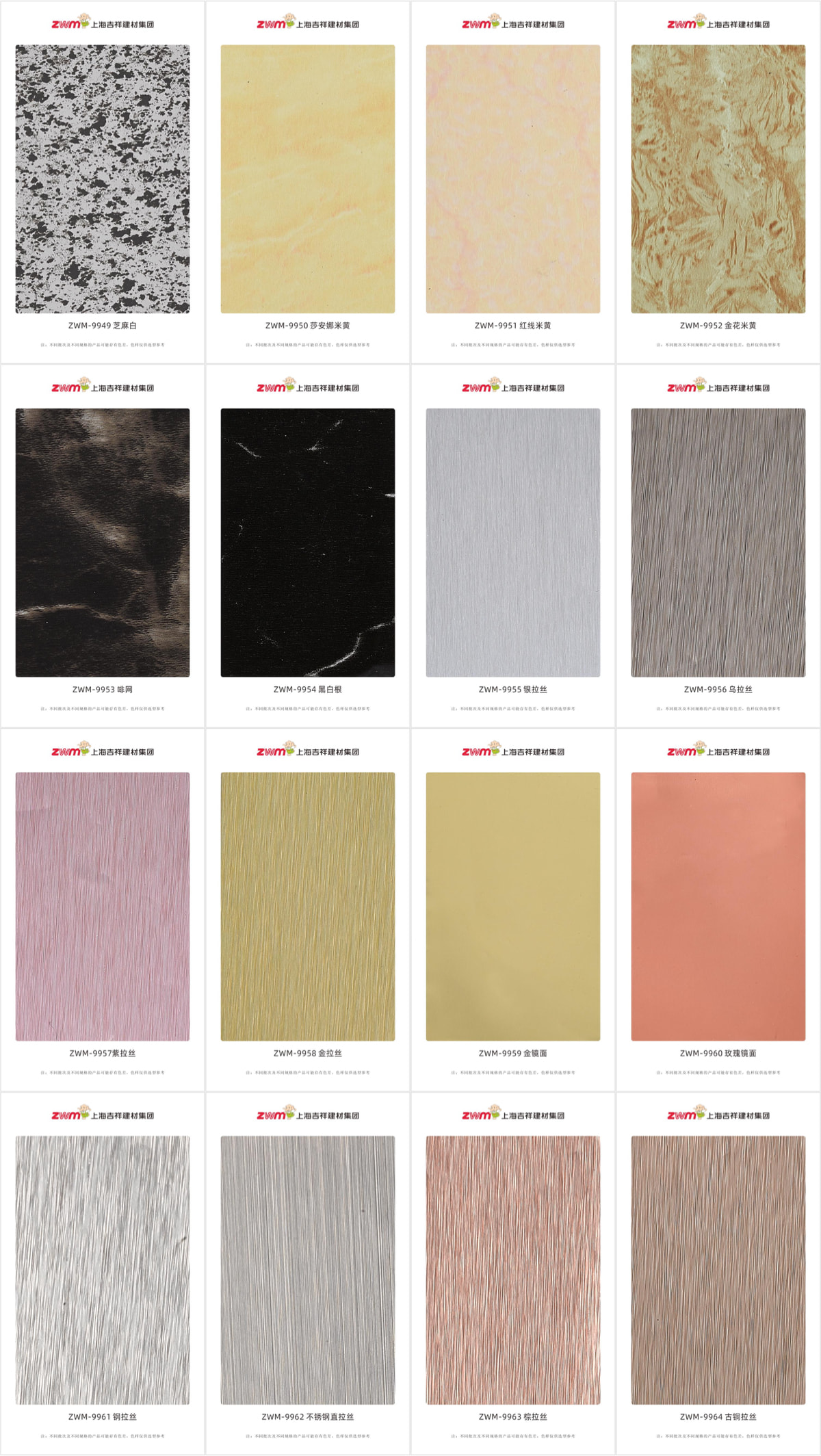

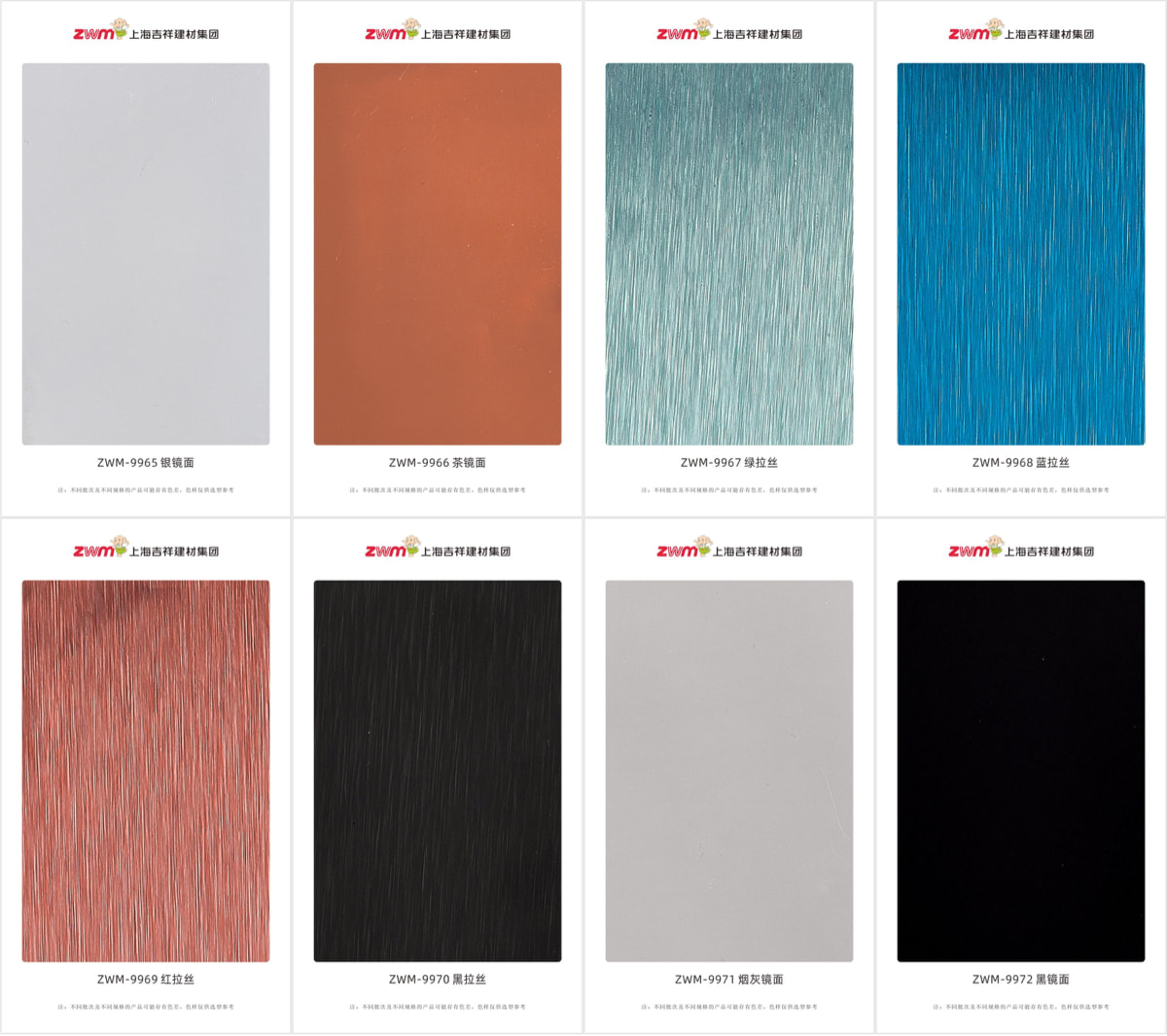

5. Surface coating: fluorocarbon resin (PVDF), polyester resin (PET) and other imitation marble and imitation wood grain surface

6. Core material: fire-retardant core material, high-pressure low-density polyethylene (PE), etc

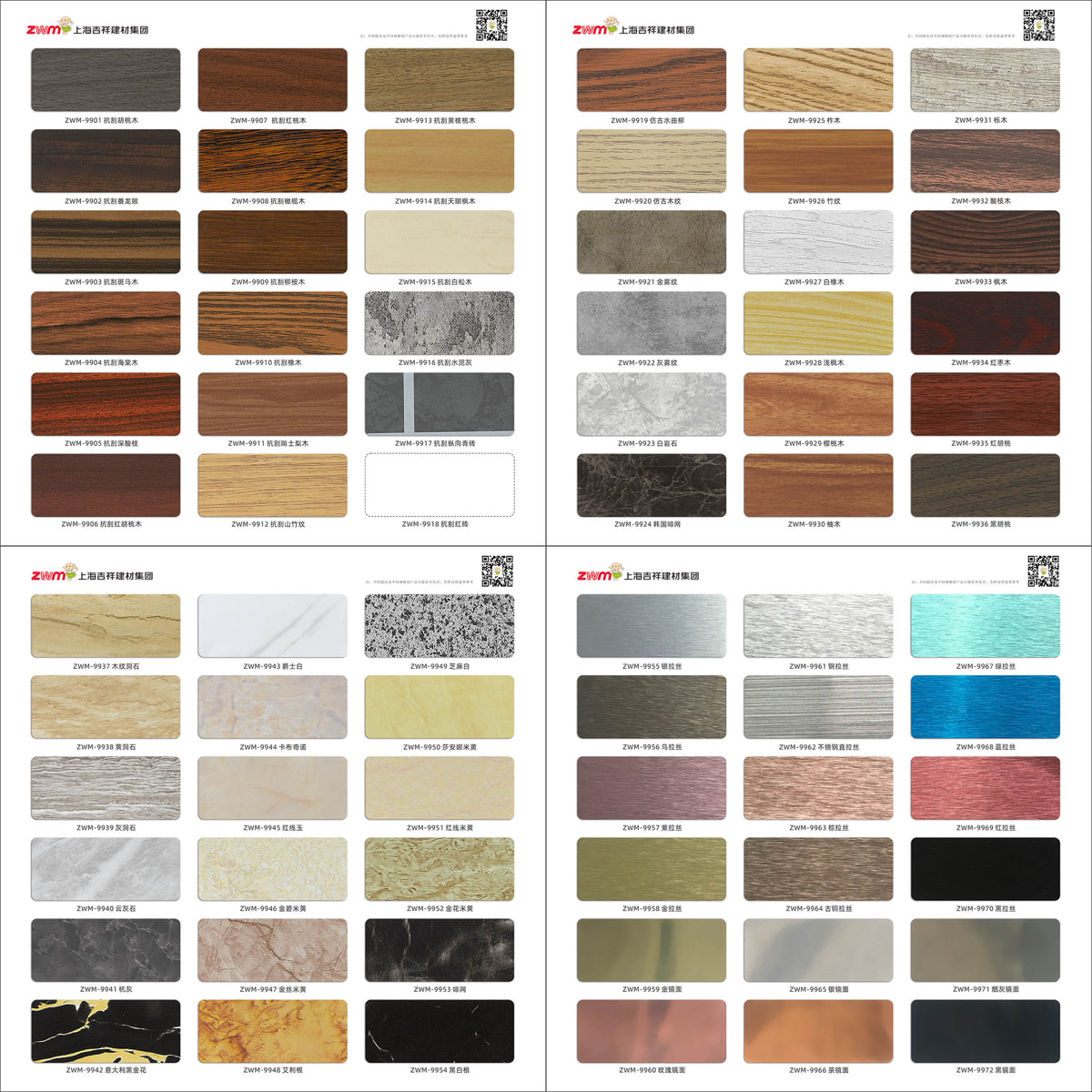

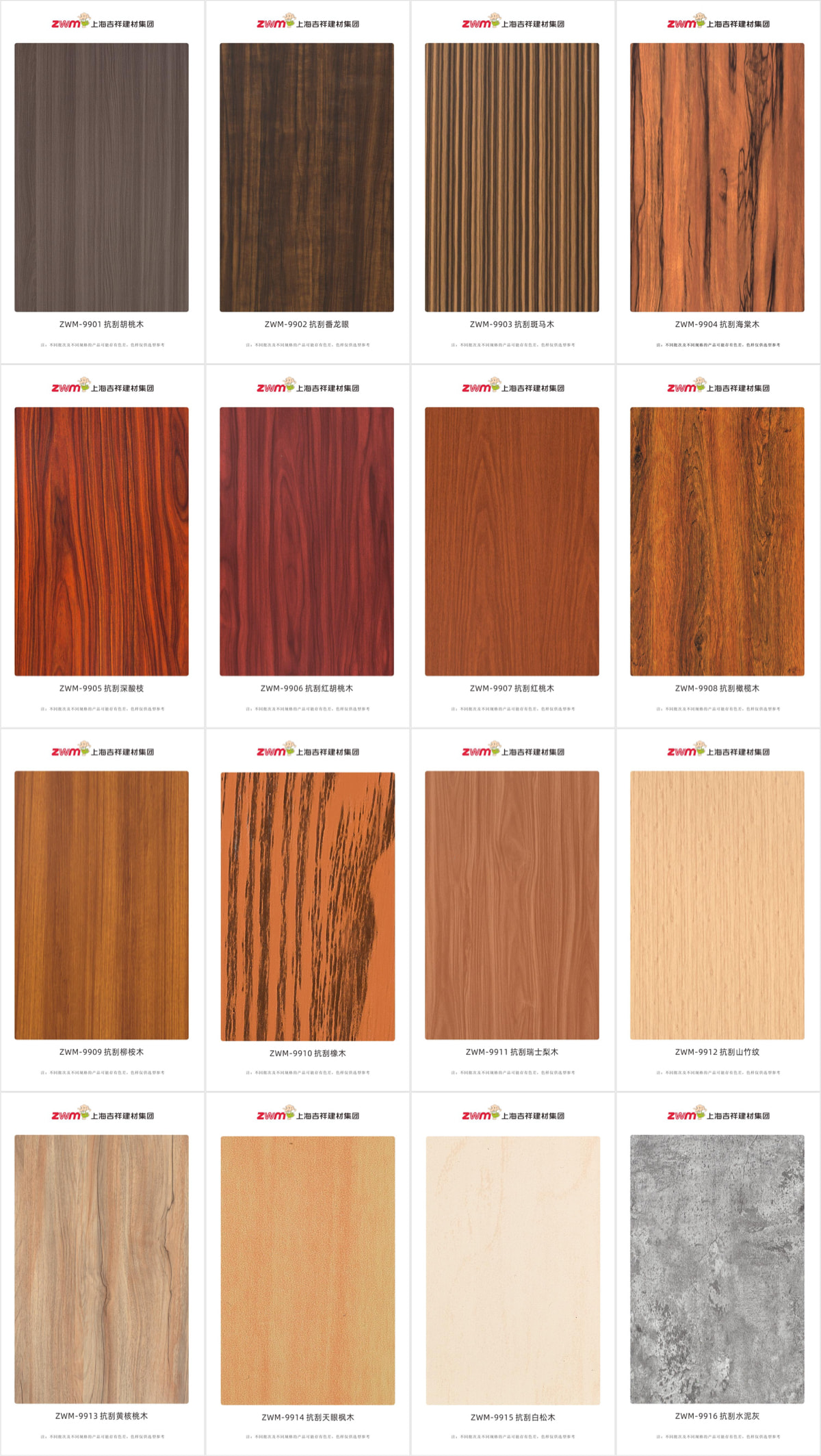

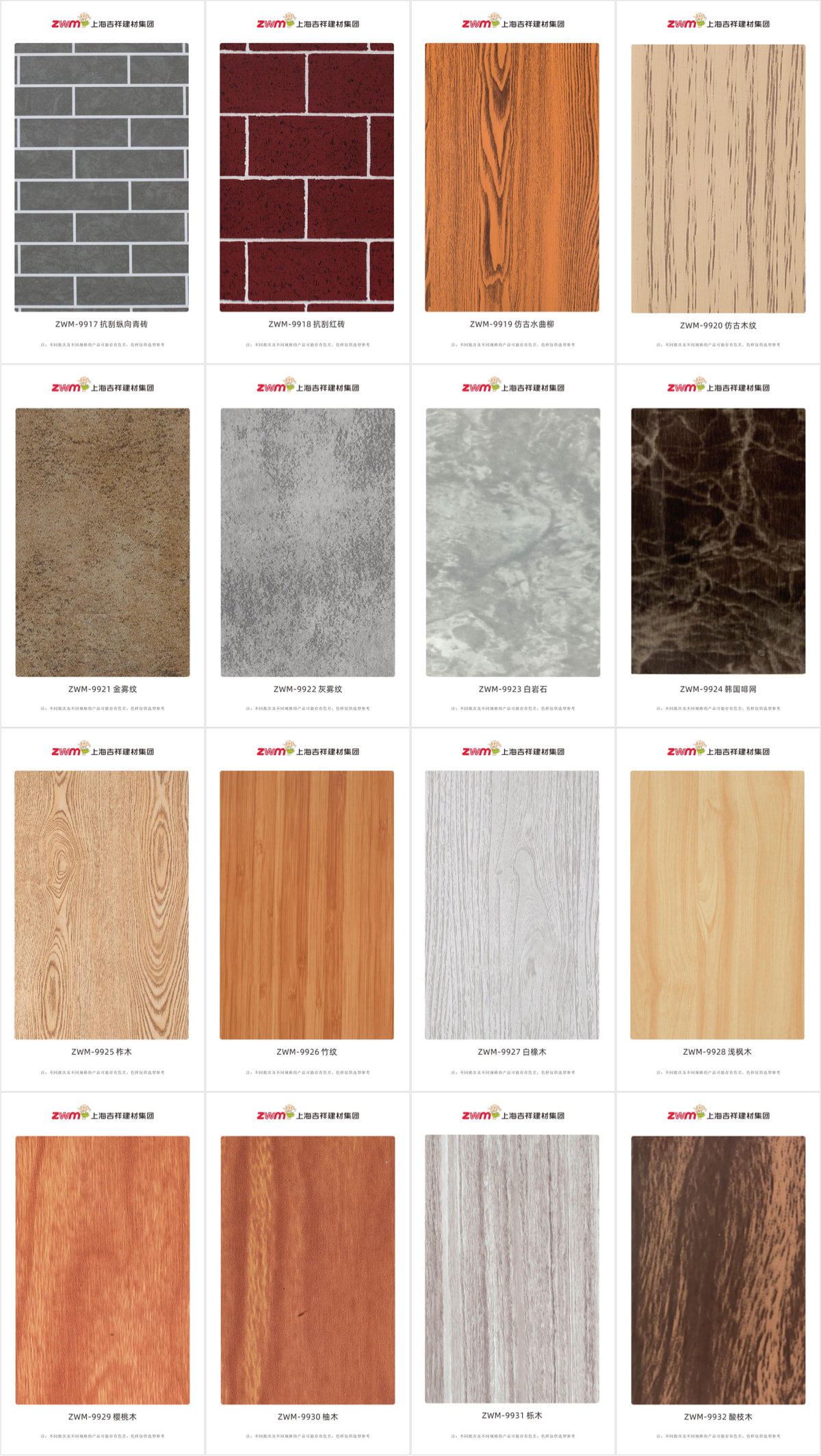

■ There are more than 40 kinds of regular colors, and special colors can be customized according to customer requirements.

Note: Due to the limitation of computer color display attribute, the color marked will be slightly different from the color of the fluorocarbon resin coating of the real product. The above colors are for reference only. The color processing of the actual order is based on the sealed samples of both parties. We can fully meet the customers' specifications for the conventional standard colors. There will be a limit on the number of products ordered in metal color and imitation marble color. The reason is that the manufacturing process of metal color and imitation marble color products with small quantity needs more coordination due to the impact of the batch production schedule. Therefore, in the implementation of a single project order, please carry out accurate accounting of the total quantity required to ensure the consistency of the color of the products produced in batches.

■ Curtain wall decoration and interior decoration of high-end residential villas and office buildings in airport terminal stations, subway malls, hotels and entertainment venues

■ Large billboard display window roadside newspaper booth book stall telephone booth traffic sentry box roadside oil station

■ Interior wall ceiling compartment kitchen bathroom skirting

■ Shop decoration, interior shelf, cabinet and column furniture

■ Train car, ship, passenger car compartment decoration

■ Renovation and reconstruction of old buildings

■ Purification and dust-proof works

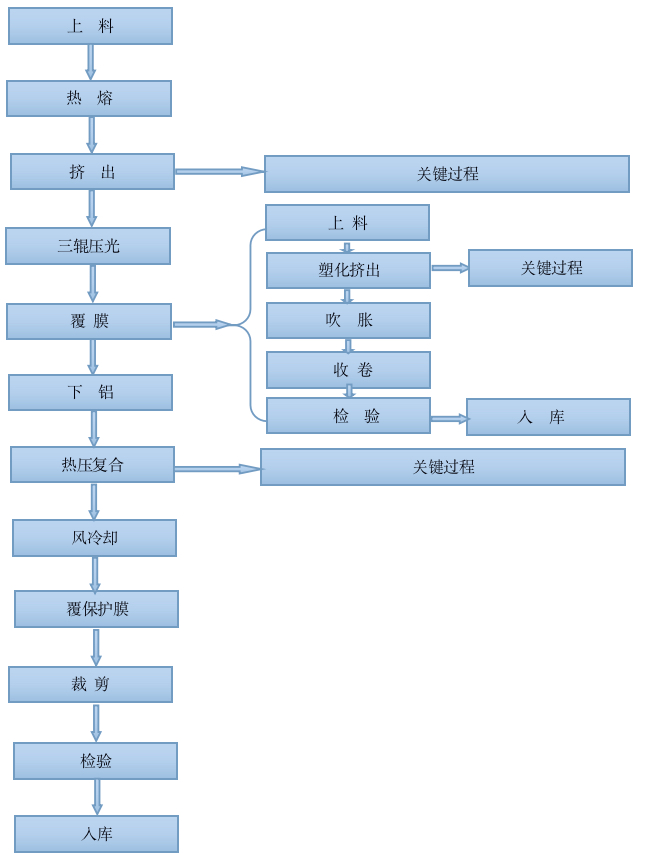

Production Flow Chart of Aluminum Plastic Plate

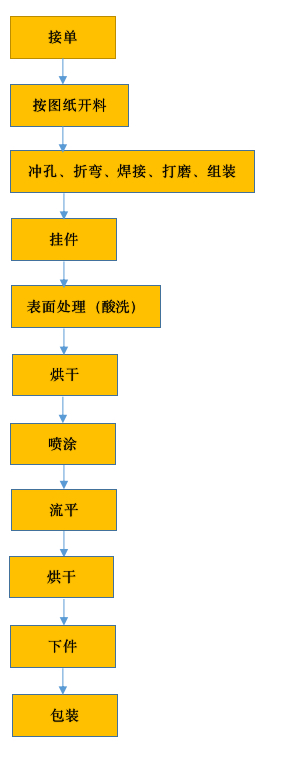

Process Flow Diagram of Aluminum Veneer

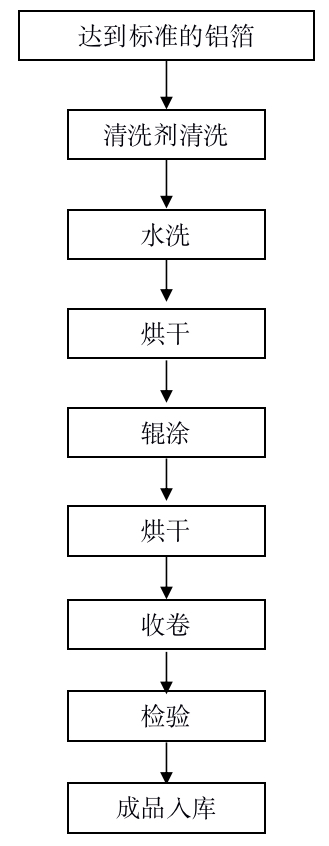

Process Flow Chart of Aluminum Coating Production

Aluminum plastic plate is a good material that can be easily processed, formed and assembled. It is also an excellent product that strives for efficiency and time. It can shorten the construction period and reduce costs. General sheet metal factory or woodworking factory equipment can easily complete its processing and assembly work. Aluminum plastic plate can: cutting, cutting, grooving, vertical evidence, keyhole, processing countersink, cold bending, cold rolling, cold folding, riveting, screw bonding, welding, clamping or gluing, painting, screen printing, sign board and advertising signboard.